Products

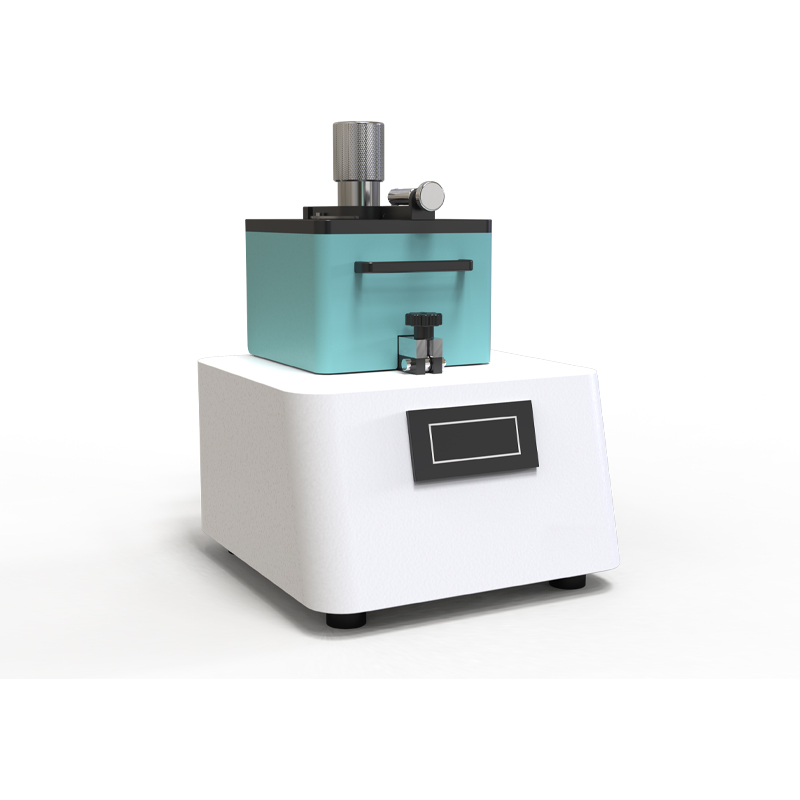

Laboratory Mill

The mortar grinder is based on the principle of traditional manual grinding. The sample is crushed by friction and compression between the mortar and the pestle. When the sample enters from the feed port, it flows inward along the direction of the mortar movement.

Product Details

The mortar grinder is based on the principle of traditional manual grinding. The sample is crushed by friction and compression between the mortar and the pestle. When the sample enters from the feed port, it flows inward along the direction of the mortar movement. After hitting the scraper, part of the sample gathers on the upper and lower contact surfaces between the mortar and the pestle, and the other part enters the rear contact surface along the mortar wall. This cyclic movement ensures the uniformity of the sample crushing.

Eccentric design of pestle and mortar

The pestle is designed eccentrically relative to the mortar. First, the mortar drives the pestle to rotate, which creates friction with the sample, thereby crushing the sample. Second, the weight of the pestle itself and the adjustable elastic force acting on the axial direction of the pestle create additional pressure, further improving the crushing effect.

Features:

Applicable to various grinding methods: supports dry grinding, wet grinding and frozen grinding to meet different needs.

Pretreatment of rough samples: optional pretreatment function to improve grinding effect.

Flexible feeding: the sample volume can be increased at any time through the feeding window, which is easy to operate.

Multi-material scraper selection: scraper material (polyurethane, polytetrafluoroethylene, beech) is optional to meet various application needs.

Tool-free position adjustment: the position of mortar and pestle head can be quickly adjusted, which is convenient and flexible.

Precise adjustment: the scale adjustment function ensures the accuracy and repeatability of pestle head setting.

Representative grinding results: through digital time and speed settings, the reliability of each grinding result is ensured.

Adapt to heat-sensitive samples: suitable for different heat-sensitive samples to ensure accurate and optimized grinding results.

Multi-material grinding tools: mortar and pestle heads provide a variety of material options to meet various application needs.

Easy to clean: simple design, easy to clean, saving maintenance time.

Technical Specifications

Model | WMG500 |

Sample Type | Hard, Medium-hard, Soft, Brittle, Fibrous, Abrasive, Temperature-sensitive Samples |

Grinding Principle | Friction |

Sample Size | 8-10mm |

Final Fineness | 10 to 20μm |

Speed | 60-180rpm |

Batch Sample Quantity | 10mL-230mL |

Time Setting | 0-99mins or Continuous |

Grinding Tool Material | Agate, Tungsten carbide, Stainless Steel, Hardened Steel,Zirconium Oxide |

Scraper Pressure | Adjustable |

Pestle Pressure | Adjustable |

Powe Consumption | 180W |

+86 21 51096910

sales@welsobio.com

marketing@welsobio.com

1-1009, National Industrial Design Park, No. 599 Jianzhu Road, Binhu, Wuxi , Jiangsu, China, 214062

Head Office: No. 439 Jinglian Road, Minhang District, Shanghai,China, 201108