Products

Microwave Digestion

Microwave digestion instrument is an advanced sample pretreatment equipment that can provide a high temperature, high pressure closed digestion environment and efficiently complete the sample digestion process in a short time.

Product Details

Microwave digestion instrument is an advanced sample pretreatment equipment that can provide a high temperature, high pressure closed digestion environment and efficiently complete the sample digestion process in a short time. This fast and efficient processing method significantly improves the work efficiency of the laboratory, while effectively reducing the risk of external contamination and sample cross contamination, ensuring the safety and accuracy of sample processing.

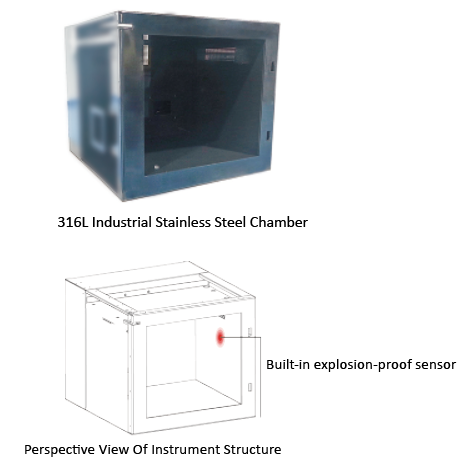

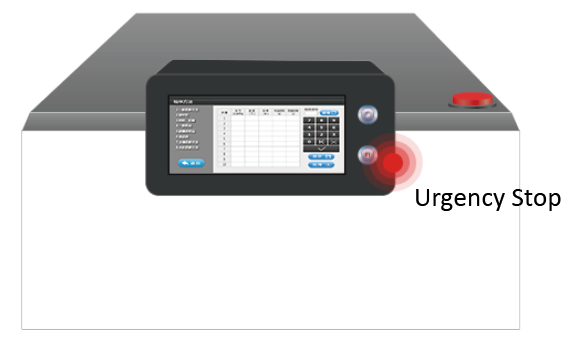

Welso WMD600 closed intelligent microwave digestion instrument attaches great importance to practicality and safety. The whole machine adopts 316L industrial stainless steel structure, and is sprayed with multi-layer PFA coating inside, which has excellent impact resistance, explosion resistance and corrosion resistance. The outer wall of the furnace cavity is equipped with an explosion-proof sensing device, which can effectively warn and suppress the spread of risks; an emergency stop button is set on the outside to quickly cut off the power supply in an emergency, eliminating accidents from the source. The multiple safety designs enable the Welso microwave digestion instrument to ensure the safety of operators while ensuring the stable and reliable operation of the equipment.

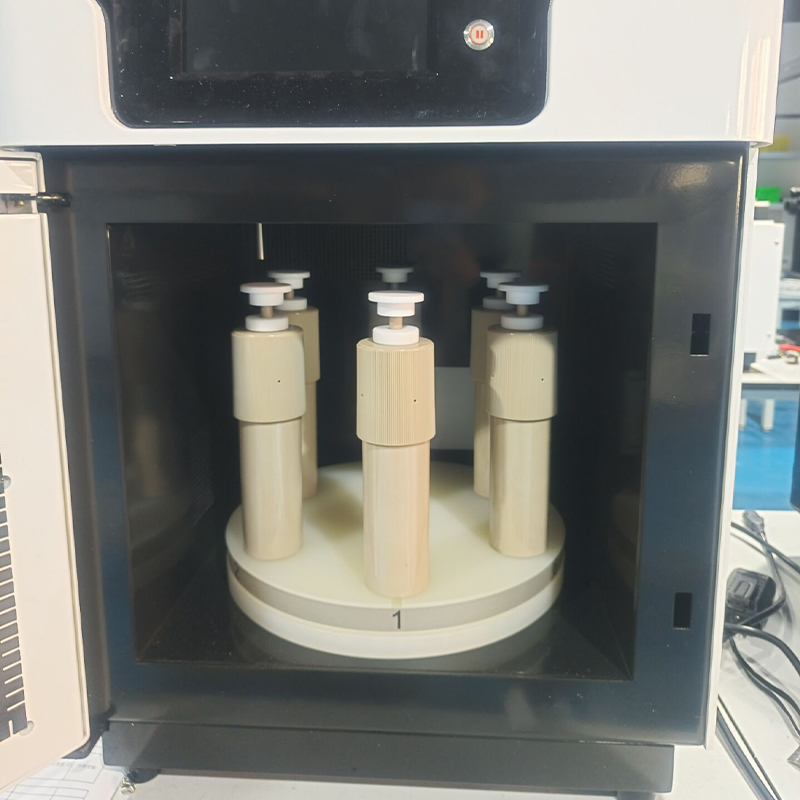

The WMD600 series includes four models: WMD600, WMD800, WMD1000 and WMD1200D. The main difference between them is the number of rotors they can accommodate: WMD600 can accommodate 6 rotors, WMD800 can accommodate 8 rotors, WMD1000 can accommodate 10 rotors, and WMD1200D can accommodate up to 12 rotors. Users can choose the appropriate model according to the experimental throughput requirements. The specific parameters are described below.

Features

High-throughput digestion capability

Supports up to 12 tanks to run simultaneously, meeting the needs of efficient pre-treatment of different types and large batches of samples, significantly improving experimental throughput.

Uniform distribution of microwave field

Adopts vertical waveguide structure and three-dimensional microwave output technology, matches harmonic power frequency, ensures uniform distribution of microwave energy in the furnace cavity, and improves digestion consistency and efficiency.

High-precision temperature control system

Configured with platinum resistance temperature control module, real-time monitoring, control and dynamic display of the temperature and temperature curve of each digestion tank, to achieve precise temperature control and ensure digestion quality.

Non-contact pressure monitoring

Equipped with optical fiber scanning high-precision pressure measurement system, non-contact real-time monitoring of the internal pressure of each tank, and synchronous display of pressure curve, improve safety and control accuracy.

Consumable-free design

Does not use explosion-proof membranes, sealing bowls and other consumable accessories, reduce long-term operating costs, simplify maintenance processes, and improve equipment economy and practicality.

High-strength structural design

The shell is made of carbon fiber reinforced polymer material, with excellent mechanical strength and impact resistance, adapting to complex experimental environments.

Intelligent touch operation interface

Equipped with an ultra-large professional color touch screen, the operation interface is friendly and intuitive, supporting intelligent interaction and full-process information display, improving the user operation experience.

Technical Specifications

Model | WMD600 | WMD800 | WMD1000 | WMD1200D |

Vessel Quantity | 6 | 8 | 10 | 12 |

Temperature Monitoring System | Temperature Monitoring: Contactless IR Sensor; Scan monitoring for each vessel Temperature Controlling Range: 50~400℃; Temperature Accuracy: +0.1C; Display Accuracy: ±0.1℃ | |||

Pressure Monitoring System | Pressure monitoring: Contactless Sensor; Scan monitoring for each vessel Pressure Controlling Range: 0~15MPaPressure Accuracy: ±0.01MPa Display Accuracy: ±0.01Mpa | |||

Vessel Volume | 100mL | |||

Sample Vessel Material | Imported TFM | |||

Protection Vessel Material | Peek+Glass Fiber | |||

Display | 7 inch Touch Screen | |||

Rotation | 360°Continuous Rotating | |||

Microwave Tank | 316L Stainless Steel tank With Corrosion-Proof Coating | |||

Microwave Power | 0-1000W(Adjustable) | |||

Microwave Leakage | <5mw/cm2 | |||

Air Exhaust | High Power Corrosion-Proof Air Blower | |||

Power | AC220V±10%, 10A, 50/60Hz | |||

Dimension | 490*560*630mm(L*W*H) | |||

Weight | 47kg | |||

FAQ

Q:Is there any consumable needs to be changed after each use?

Q:How to clean the vessels after each run?

Q:Is it possible to put sample in one vessel and keep other vessels empty and start digestion?

Q:What is the volume in each vessel?

Q:How many samples can be digested in each run?

+86 21 51096910

sales@welsobio.com

marketing@welsobio.com

1-1009, National Industrial Design Park, No. 599 Jianzhu Road, Binhu, Wuxi , Jiangsu, China, 214062

Head Office: No. 439 Jinglian Road, Minhang District, Shanghai,China, 201108